Flexible Intermediate Bulk Containers Manufacturers

Our Flexible Intermediate Bulk Containers (FIBCs) – commonly known as bulk bags, FIBC totes, or FIBC bulk container bag – are tailor-made to suit your specifications. We are the premier flexible intermediate bulk containers manufacturers that provide custom services across the globe and across multiple industries.

Our FIBCs are highly customizable and can be created to accommodate your specific handling, transportation and storage needs.

Flexible intermediate bulk container types

A flexible intermediate bulk container is undoubtedly the most preferred and cost-efficient packaging solution for storing and transporting bulk materials like granules, chemicals, and pharmaceuticals.

However, with different material requirements, sizes, and designs, choosing the right bulk container bags can be a daunting task. That is why, as FIBC manufacturers, we offer a wide range of solutions to cater to various small to large-scale industries.

These FIBC types include Type A, B, C, and D, which differ on their electrostatic properties and grounding requirements. Each FIBC type serves well in specific industries, and understanding their differences can help industries make the right choice in terms of safety and environment protection.

01. Type A flexible intermediate bulk containers (no electrostatic protection)

Type A flexible intermediate bulk container bags are primarily used when you don't need to handle hazardous materials since they don't provide any static protection. Given their lack of static protection, it is crucial to avoid employing Type A bags for storing or moving inflammable substances, or employing them in environments that are prone to catch fire.

Primary Uses for Type A FIBCs:

- Non-hazardous environments & materials.

- General storage & transporting needs for all industries.

Do NOT use for:

- In the presence of a combustible atmosphere with a low minimum ignition energy of less than 1,000mJ.

- Areas where there are inflammable gases or materials.

- If you are moving any dangerous or inflammable materials.

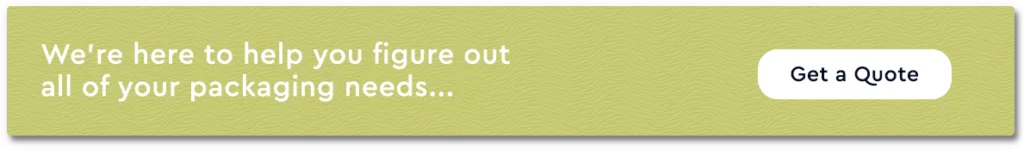

02. Type B FIBC bulk container bag (Surface breakdown voltage of <6kV)

Type B bulk bags are similar to Type A bulk bags in that they do not have a built-in static electricity dissipation mechanism. However, the key difference is that the materials in Type B bulk bags have a low breakdown voltage to prevent propagating brush discharges from arising, which can be highly energetic and hazardous. Even so, our Type B flexible bulk containers cannot be categorized as "antistatic" since because they can't discharge electrostatic charge.

Primary Uses of Type B FIBCs:

- Situations with less than 3mJ ignition and dust energies.

- Environments without gases & solvents.

- Transportation of flammable but DRY powders.

Do NOT use for:

- Transporting general hazardous materials, aside from those mentioned above.

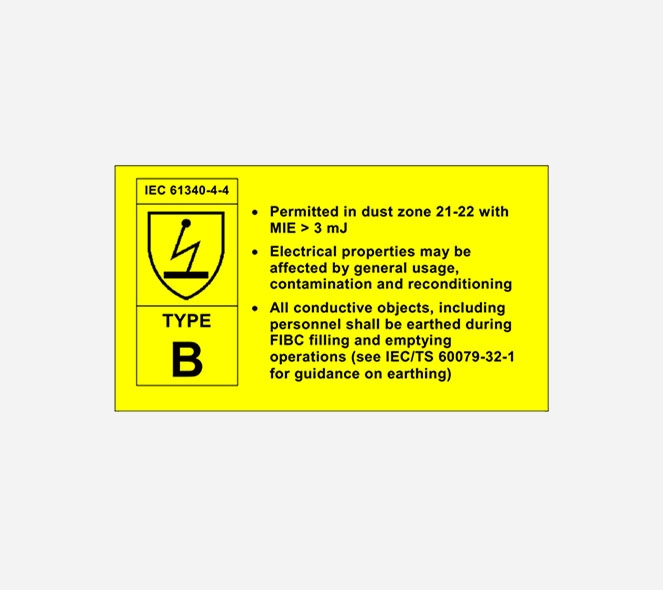

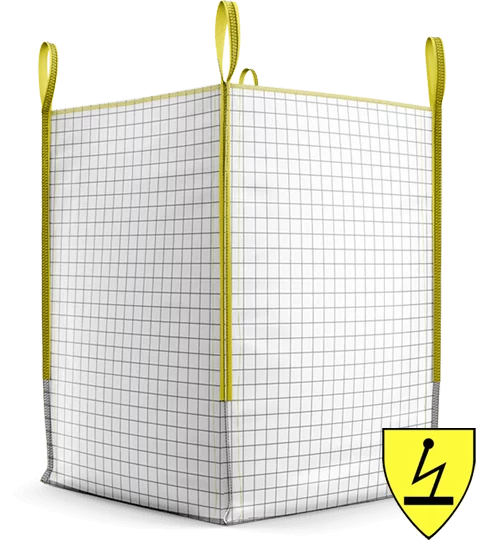

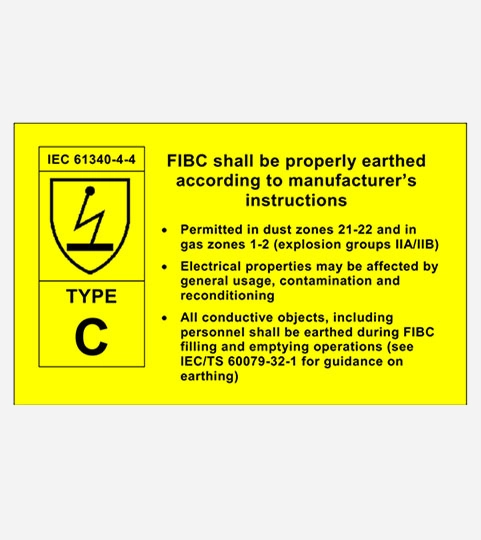

03. Type C flexible intermediate bulk container (Grounded & electrically conductive)

Our Type C flexible container bag is our groundable or conductive solution. Originally made from 100% conductive materials, they're constructed in a grid structure from non-conductive polypropylene interwoven with conducting yarns. This structure and grounding capabilities are critical to the safe use of our Type C flexible bulk container.

Type C conductive FIBCs main uses:

- In the presence of combustible dusts and flammable gases or vapors.

- Transportation of flammable powders.

Do NOT use for:

- In a less than 1,000mJ minimum ignition energy flammable atmosphere.

- If there's any resistance to a groundable point.

- In the absence of a ground connection.

- If the ground connection medium is damaged.

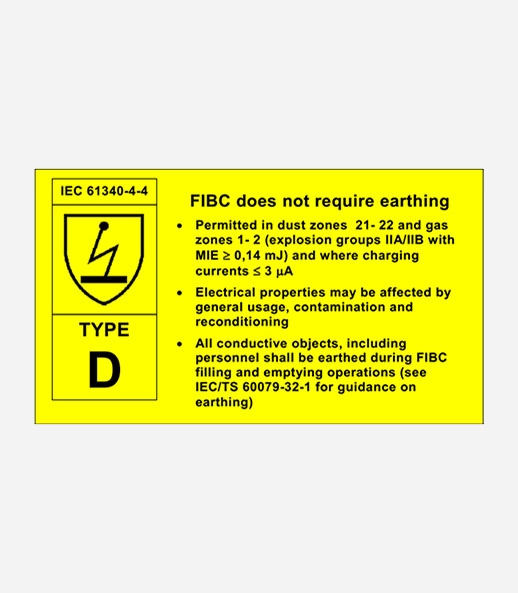

04. Type D bulk container bags (CROHMIQ static dissipative or antistatic)

As FIBC bag manufacturers, our sole purpose behind our anti static bulk bags is to safely prevent propagating brush discharges, brush discharges and incendiary sparks, without needing grounding. This is due to the CROHMIQ fabric, eliminating the risk of grounding failure, which is always present when conductive grounded FIBCs (Type C FIBCs—see above) are used.

Type D antistatic FIBCs uses:

- In the presence of combustible dusts and flammable gases or vapors.

- Transportation of flammable powders.

Do NOT use blue CROHMIQ bulk bags for:

- Contaminated or coated conductive material on the FIBC surface. For example, grease or other flammable and/or combustible materials.

Benefits of using Palmetto as FIBC manufacturers

As a world-class FIBC bags manufacturer, our product range offers the following advantages:

- Multiple fill and discharge FIBC bags.

- Available with tube or form-fit custom liners made with linear low-density polyethylene (LLDPE) and low-density polyethylene (LDPE). Liners are also available with foil laminates.

- Available in multiple lifting, hauling, and harness options.

- Available with coated or uncoated finishing, including BOPP film.

- Available in UN Specifications for levels 1-3. FIBCs are certified in independent labs in the country of their origin and carry UN certification labels (see our UN FIBC product).

- Groundable (Type C).

- Static dissipative (Type D) utilizing CROHMIQ ® Fabric.

How do flexible intermediate bulk containers compare to other solutions?

Knowing how to augment or replace your current containers can help you fit FIBCs into your modernization plans.

Here are a few container types that can be swapped or augmented with an FIBC tote:

- Paper bags

- Paper boxes

- Plastic hand-carry totes

- Metal shipping containers

- Metal and plastic hoppers

- Plastic bags/vessels for draining liquids

- Metal or plastic liquid containers

Why more companies are moving to FIBC bag manufacturers over other solutions

Replacing Paper Containers

If you need to carry wet solids, liquids, slurries, or other moist products, paper simply isn’t a good option.

While some reinforced paper products can be filled or sprayed with a liner, the paper will eventually get soaked and deteriorate. Cheap paper bags can’t stand up to FIBCs when you consider the FIBC reuse and recycling potential.

FIBCs perform the same job as paper containers, but are more flexible. This means not having to align your storage into square shapes and wasting space because of bulky corners for odd-shaped products.

Replacing Plastic Carrying Containers

Hand-carry containers are easy to grip, but should your team be carrying them by hand at all?

While hand-carry totes are a great idea when a lot of small objects need to be carried quickly, any moderately heavy process is faster with an FIBC. Keep a few totes on hand for versatility, but consider using FIBC bags and carts to quickly load, cinch, and push materials.

Even better, using an FIBC or liner inside of bags allow easy transportation and quick switching for workers who want to carry.

Enhancing Shipping Containers

If your materials produce a lot of dust, are difficult to clean up, or simply can’t be wasted on the walls of a shipping container, use FIBC liners.

Liners can be added to containers, boxes, bags, or any surface if you share the dimensions or discuss the project plans with a Palmetto Industries consultant.

Replacing or Enhancing Hoppers

Instead of using metal or plastic funnels or hoppers, custom FIBCs can be designed with spouts that can stop and go with a cinch or control valve.

This allows your process to store and transport materials in the same container used by filling. No need to tip or turn over; custom filling ports are a safer way to deposit what you need.

Replacing or Enhancing Liquid Loaders

Just as solids can be deposited easily, FIBCs with liners can be filled with liquids for storage, transportation, drainage, and even mixed with approved, non-destructive tools.

Not sure if your process is too destructive for liners? Talk with a Palmetto Industries professional to figure out a solution or clever workaround.

Replacing or Enhancing Liquid Containers

If your industrial process simply needs to store liquids, an FIBC and a liner are all you need.

FIBCs can be designed in multiple shapes and configurations. A flat-bottom FIBC can make standing liquid containers easier, and custom loops can help you rig cages, bars, support, or other mounts to hold the FIBCs open as a makeshift vat.

Why Choose Palmetto Industries As Your FIBC bags manufacturer?

As reliable and established FIBC bulk bag manufacturers, our worldwide network of distribution centers means you don’t have to worry about whether your FBIC’s will arrive on time.

Contact Us Now About Our FIBC Bags Prices & Solutions

Contact us today to see for yourself what customers around the world have known for over 25 years – Palmetto is the go-to name in packaging. Call us today at 706-608-8023.