Why Choose Our Woven Polypropylene Bags?

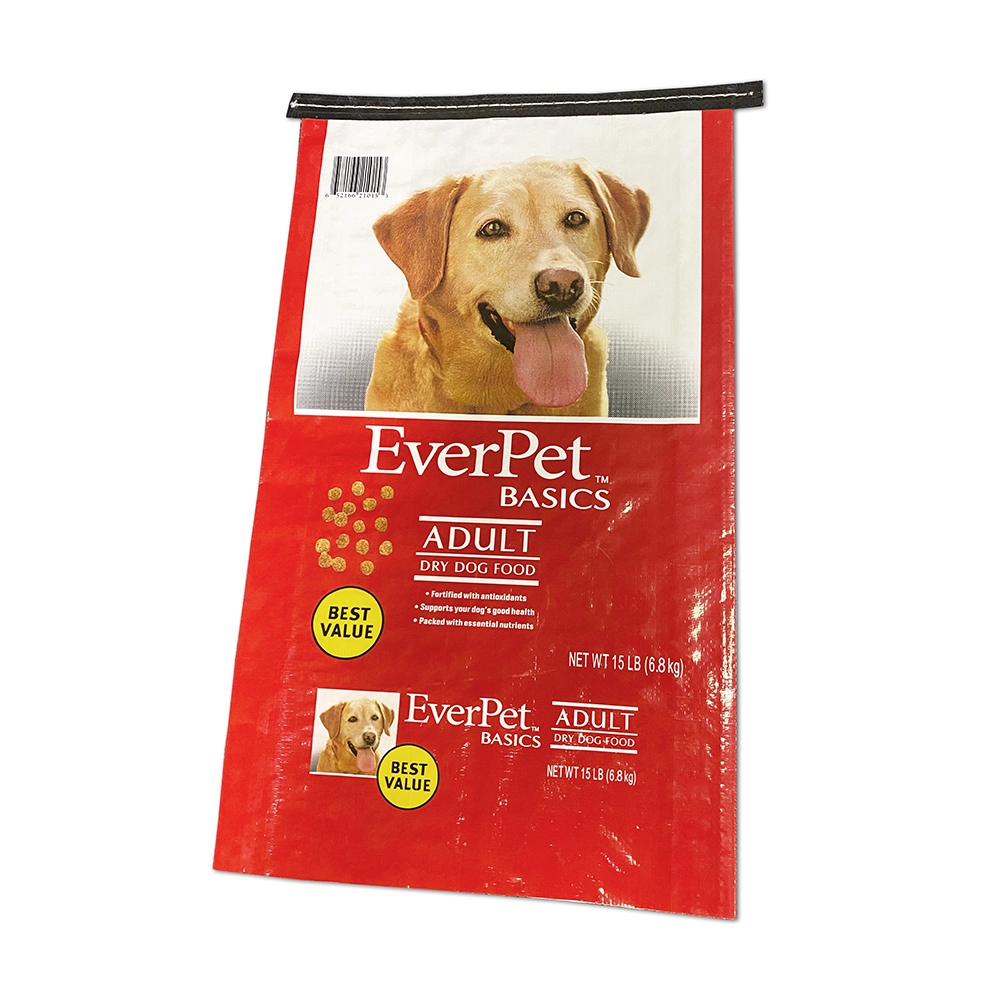

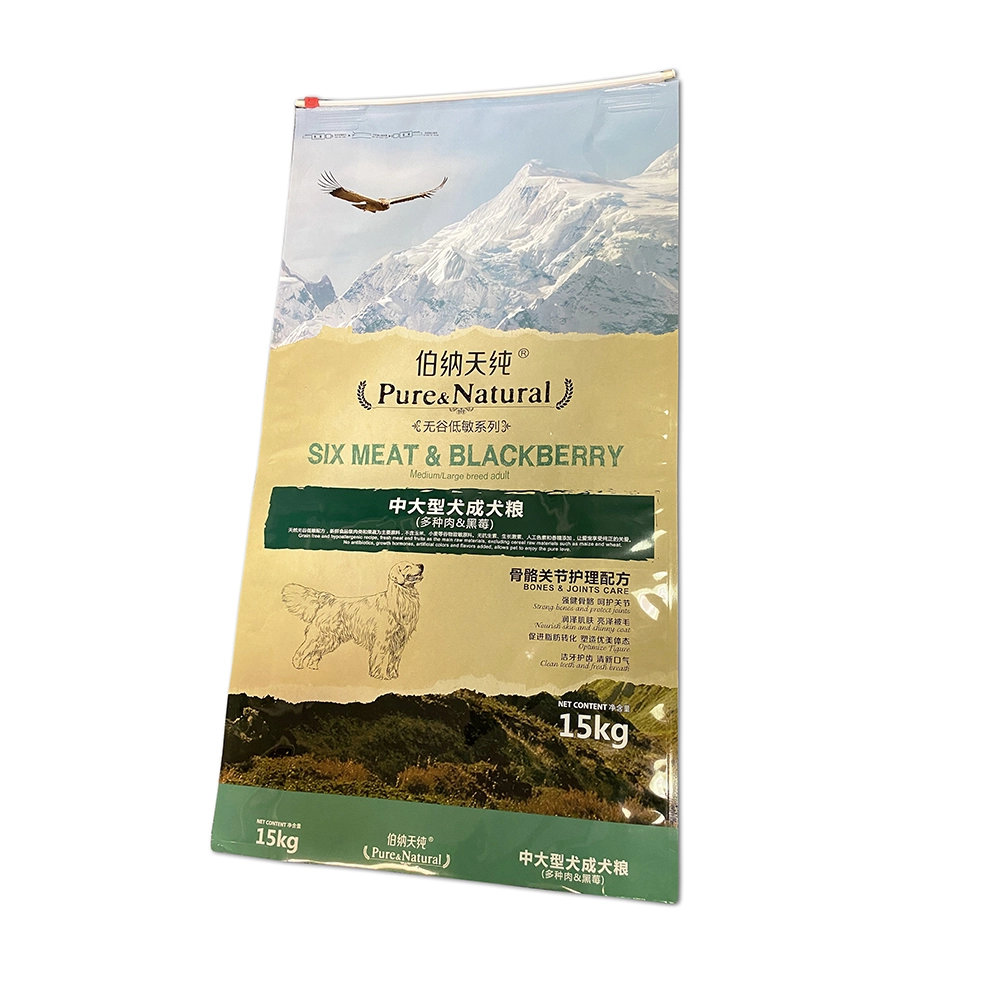

Woven polypropylene bags are the most widely-chosen bags in the packaging industry by virtue of their versatility, flexibility, and strength. We produce large and small woven polypropylene bags that can be custom made to your specifications such as mesh, denier, tape width, color and sizes. Commonly used for products such as: animal feed, rice, sugar, beans, seeds, fertilizers, sand, and cement. Our in-house, 10-color rotogravure printing allows you the ability to customize your woven polypropylene bags with photographic detail and eye-catching graphics.

Common Uses For BOPP Bags

- Pet Food

- Seeds

- Grasses

- Soil

- Animal Feed

- Fertilizer

- Sand

Why Choose Palmetto Industries As Your BOPP & PP Woven Bags Manufacturer?

Vertical Manufacturing

From resin to bag, we customize your product to suit your exacting needs. Beginning with a twin screw computerized vacuum fed extruder, we manufacture an array of fabric styles, weights, designs and performance levels. Our 4, 6 and 8 shuttle Starlinger looms with ultra-sonic slitting feed our state-of-the-art lamination and highly specialized assembly departments. From sensor alignment on the tuber to final inspection, your products are meticulously crafted with the highest of standards.

Quality Graphics

Time and again, the durability and exactness of our 10 color rotogravure press proves its value over Mexographic printing and guarantees the highest quality graphics available. High definition print capability offer lifelike color with photographic detail.

In-House Design

We employ a full service Graphics Team offering assistance in design concept, layout, vectorizing and proof development. Quick turnaround allows your products to rapidly enter the production queue and greatly reduce lead-times thus reducing the need for voluminous inventory.

Custom Specs

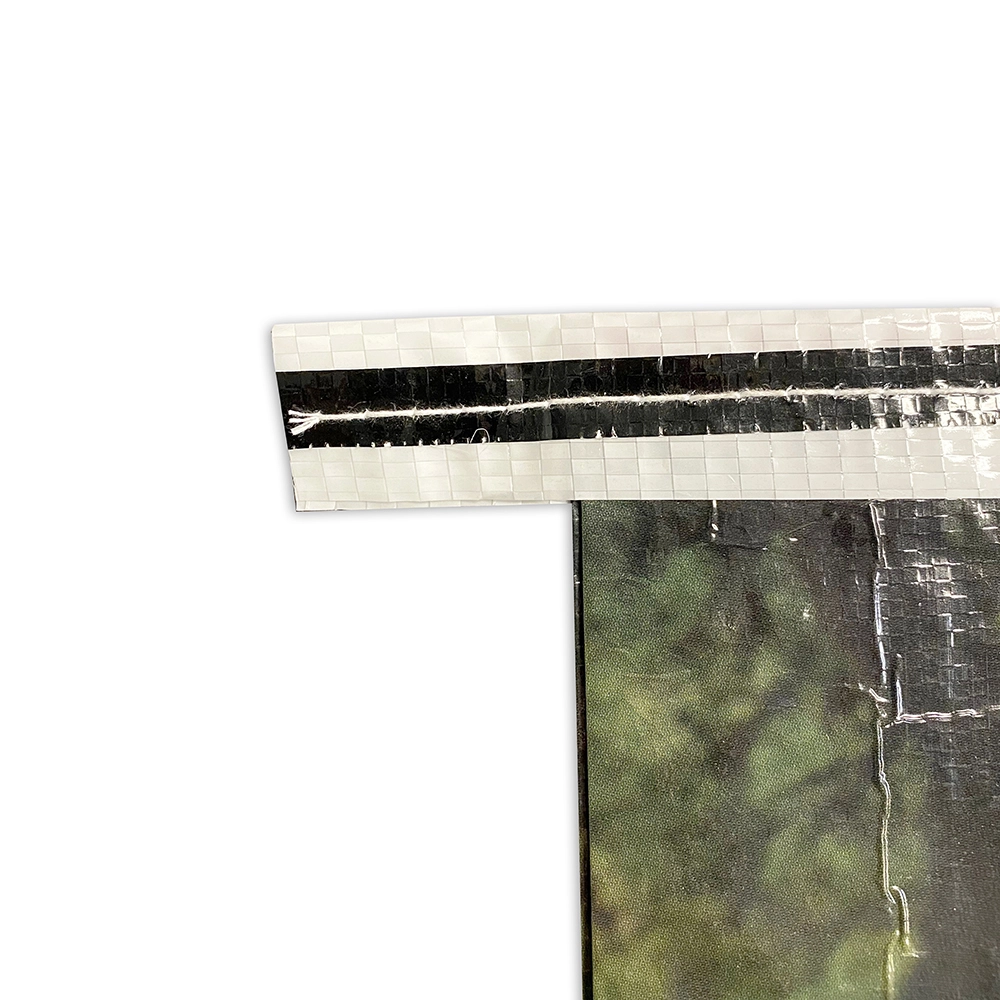

Our vertical polypropylene manufacturing unit allows us to custom manufacture any fabric specifcations required. From a 360 degree printed backseam design with standard 9×9 mesh, 1000 denier 80 gsm fabric with 18 micron Llm gauge to a specialized micro-perforated circular weave with anti-skid treatment and EZ Open closure, we can satisfy your handling and marketing requirements.

PP Woven Sack Specifications

- Backseam or circular design

- UV inhibitors added

- Available in a variety of substrates with laminate coatings, including BOPP film

- Rotogravure and flexographic printing up to 10 colors with photographic detail

- Standard or easy open closures

- Available with perforations

Our BOPP Bag Printing & Design

This biaxially oriented polypropylene film is laminated to the bags for a highly printable surface and attractive, eye-catching packaging. Palmetto’s in-house, 10-color rotogravure printing allows you the ability to customize your woven polypropylene bags with photographic detail. Our trained staff will be more then happy to assist you with your printing needs from design layout to the final printing plates/cylinders.