OCEAN CONTAINER LINER OPTIONS FROM PALMETTO:

Palmetto Industries is a worldwide manufacturer of sea bulk container liners and dry bulk container liner bags, offering full-service and support for all aspects of the bulk shipping process. Our bulk liners and bulk bags are utilized by companies large and small around the world to realize the efficiencies of shipping via containerized bulk and are designed and produced in a high-end air conditioned environment with BRC and AIB certification. With the assistance of our global network and expanding manufacturing base, we offer a comprehensive silo-to-silo program designed to suit your requirements. We are more than suited to be your container liner supplier.

FRONT SPOUT/BACK FILL CONTAINER LINERS

- Can be Installed inside the container liner for 20ft/ 30ft/40ft/52ft size shipping container.

- Loaded from the door end using a belt thrower, pneumatic pump, conveyor, or elevated to load under gravity depending on the loading system, or product being loaded.

- Capable of carrying a huge range of free flowing granular, powder, pellet, or flaked products, both food grade and Industrial grade.

- Designed for loading or discharge with one, or both doors open.

Available in food grade high tensile co-extruded LLDPE film offering excellent moisture (Water vapor transmission rate – WVTR) barrier properties and Antistatic/Dissipative Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) barrier properties as well as static control properties. Highly durable and easy to install, our container liners maximize the container payload, reduce costs, and minimize the environmental impact. All component parts are 100% recyclable.

WET HIDE/OPEN TOP CONTAINER LINERS

- Can be Installed inside any size shipping container, trailer, or railcar.

- Open ended, open top, top loading, or end filling.

- Food grade high tensile co-extruded LLDPE film offering excellent moisture (Water vapor transmission rate – WVTR) barrier properties.

- Antistatic / Dissipative Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) barrier properties as well as static control properties.

TOP FILL CONTAINER LINERS

- Can be Installed inside the container liner for 20ft / 30ft / 40ft / 52ft size shipping container.

- Loaded from the top hatches via gravity fill.

- Capable of carrying a huge range of free flowing granular, powder, pellet, or flaked products, both food grade and Industrial grade.

- Designed for discharge via the letterbox hatch or hatches at the base of the container end.

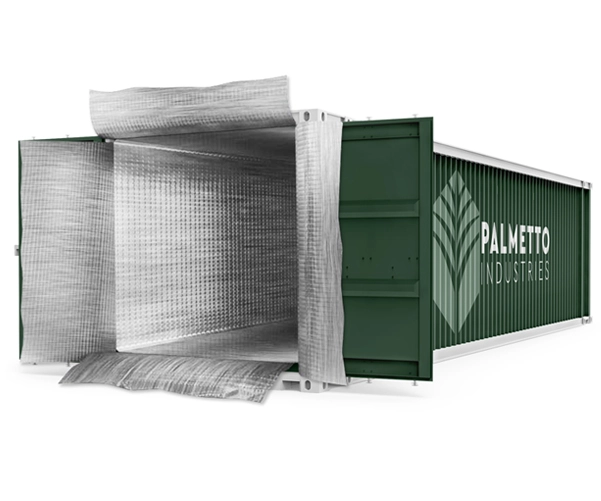

THERMAL CONTAINER LINERS

- Can be Installed inside any size shipping or bulk container.

- Open ended, top loading or end filling via loading spouts.

- Excellent protection for products which may deteriorate due to odour, light, oxygen or moisture ingress.

- Aluminum barrier foil laminate co-extruded PE/PET Aluminum Foil/co-extruded PE.

- Woven PP bulkhead for End filling liners.

- Up to 80 times more effective than 125mu PE film at preventing moisture damage.

- Foil liners can be completely sealed for airtight containment.

BARLESS CONTAINER LINERS

- Can be Installed inside any size shipping container.

- Loaded from the door end using a belt thrower, pneumatic pump, conveyor, or elevated to load under gravity depending on the loading system, or product being loaded.

- Capable of carrying a huge range of free flowing granular, pellet or flaked Industrial grade products.

- Designed for loading or discharge with one, or both doors open.

- Made from Woven HDPE or Woven PP fabrics offering high strength with Antistatic/Conductive fabric grades are available as well.

FLUIDIZING CONTAINER LINERS

- Can be Installed inside any size shipping container.

- Full or partial fluidisation available. Can be controlled section by section, both end of the container.

- Capable of carrying a huge range of hard to flow and compactable products such as fly ash, Calcium carbonate, flour and talc.

- Virgin Food grade high tensile co-extruded LLDPE film offering excellent moisture (WVTR) properties with slip special film.

- Quickly fluidises heavily compacted product to allow an easy flow and controlled discharge.

Why Choose Palmetto Industries As Your Container Liner Bags Manufacturer?

Shipping container liners have many benefits and uses for transporting dry bulk and fluid materials. The main benefit being keeping a clean and dry shield between the product and the interior of the container. They also keep the container free from residue and protect the product in use from contamination. This form of bulk container liners also results in saved cost and time by reducing the amount of packaging needed to ship large amounts of food, chemicals, minerals, and waste. They are also a time saver, allowing for easy install, loading, and discharging. Palmetto Industries is your go to choice for container liners suppliers and container liner bags manufacturers, specializing in sea bulk container liners and dry bulk container liner bags.