At Palmetto Industries, our Type A bulk bags are the industry standard used for the most common applications of storing and transporting dry goods for all industries, including agriculture, landscaping, construction, and many others.

Manufactured with conventional woven polypropylene, they do not have any mechanism for dissipating static electricity and will not prevent highly energetic and dangerous propagating brush discharges. 4 reinforced lifting loops on each corner allow the bag to be moved with a forklift. Click here to view all of the various construction types.

Why Choose a Type A Bulk Bag?

A Type A FIBC bag is the industry’s most common and cost-effective choice for storing and transporting dry, flowable materials. Designed for general-purpose use, FIBC Type A bags are made from plain woven polypropylene with no static protection. This makes them ideal for products that are not flammable, and for use in environments where there’s minimal risk of static discharge.

If your operation handles non-combustible materials like sand, gravel, grains, or powdered chemicals in a non-hazardous setting, Type A bulk bags are the reliable, budget-friendly solution.

Go ahead and click the button below for a tailored quote for a swift response!

Type A FIBC Bag Features

Palmetto Industries' Type A bulk bags are constructed to meet your toughest industrial packaging demands. Our bags are manufactured using 100% virgin polypropylene, offering high strength and consistent performance in a wide range of environments.

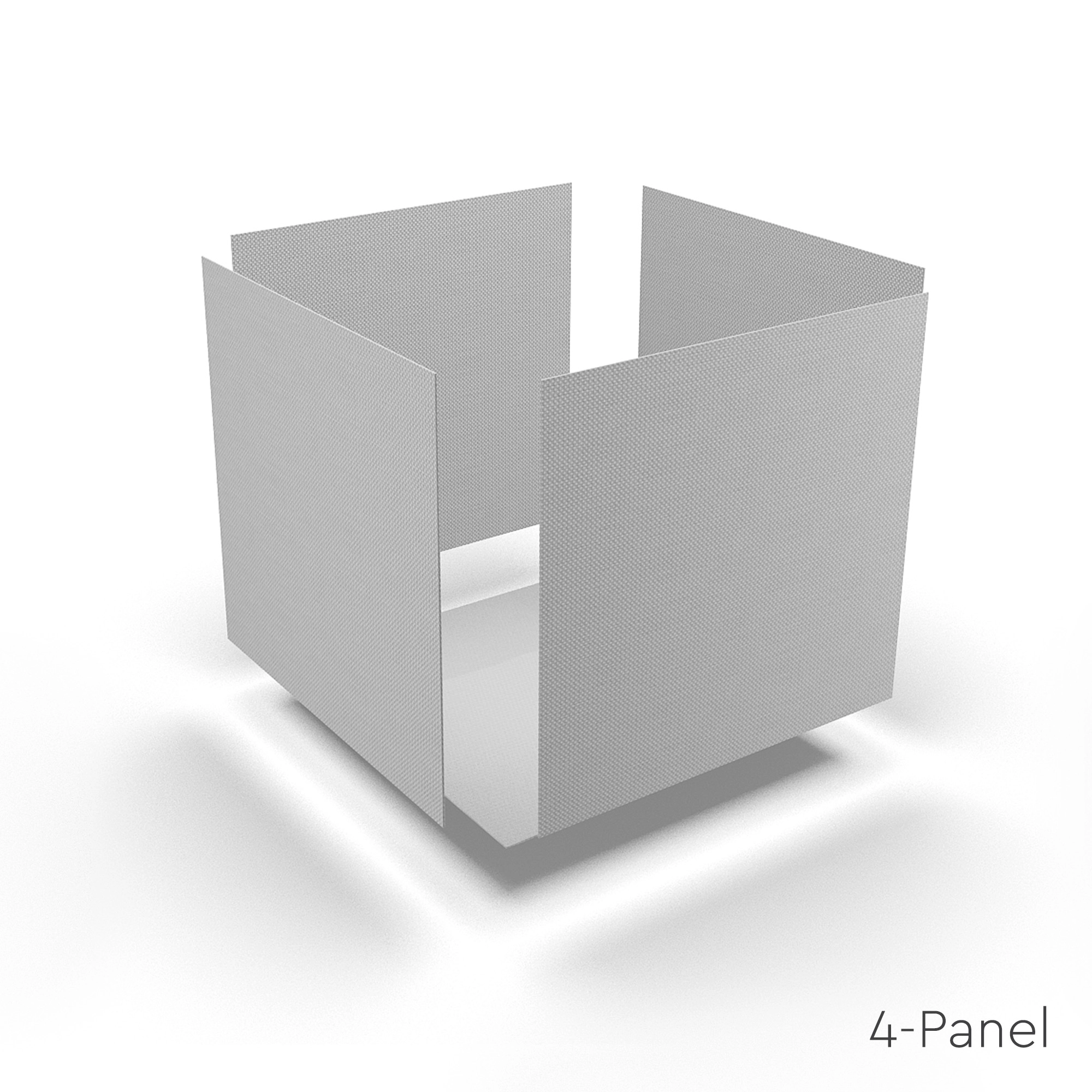

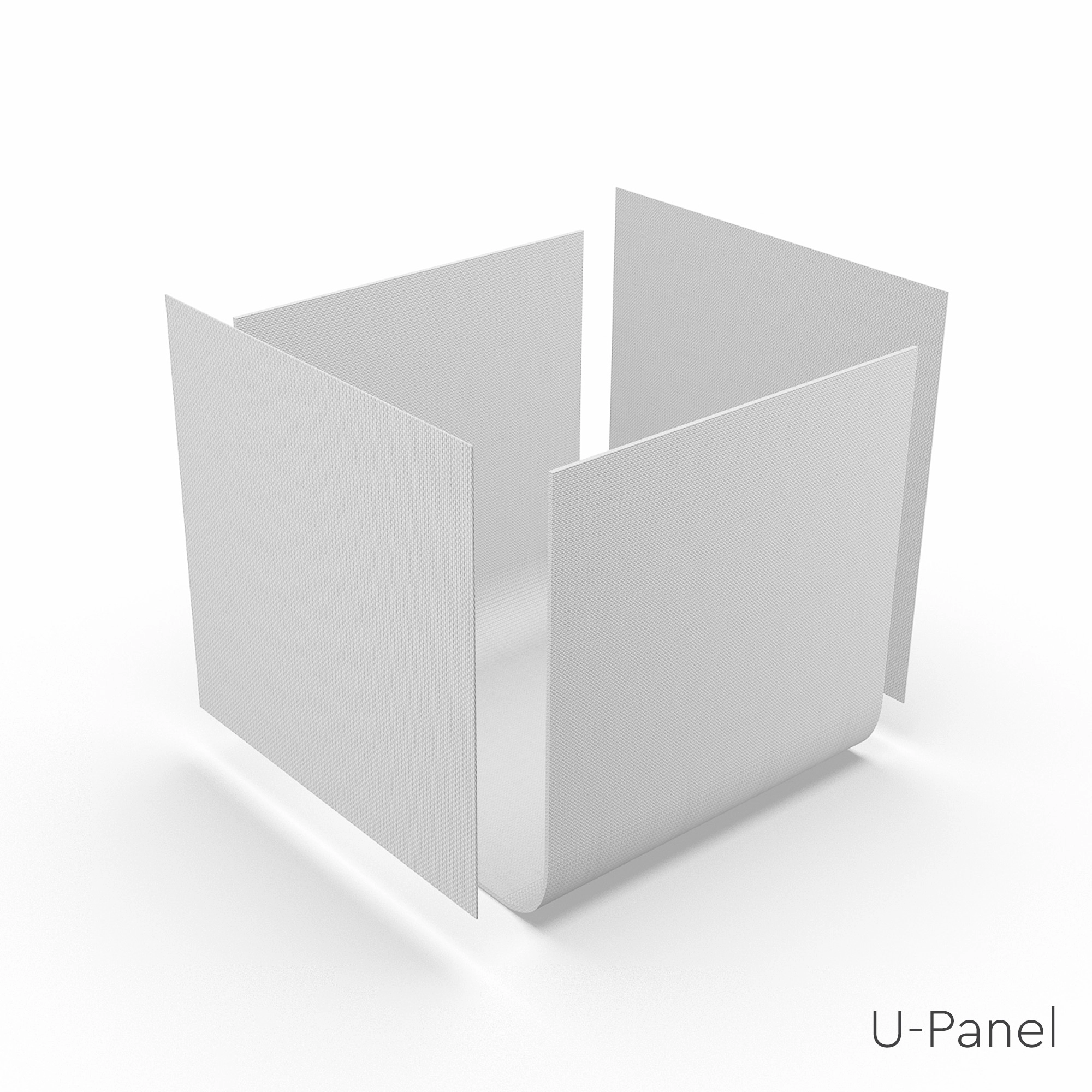

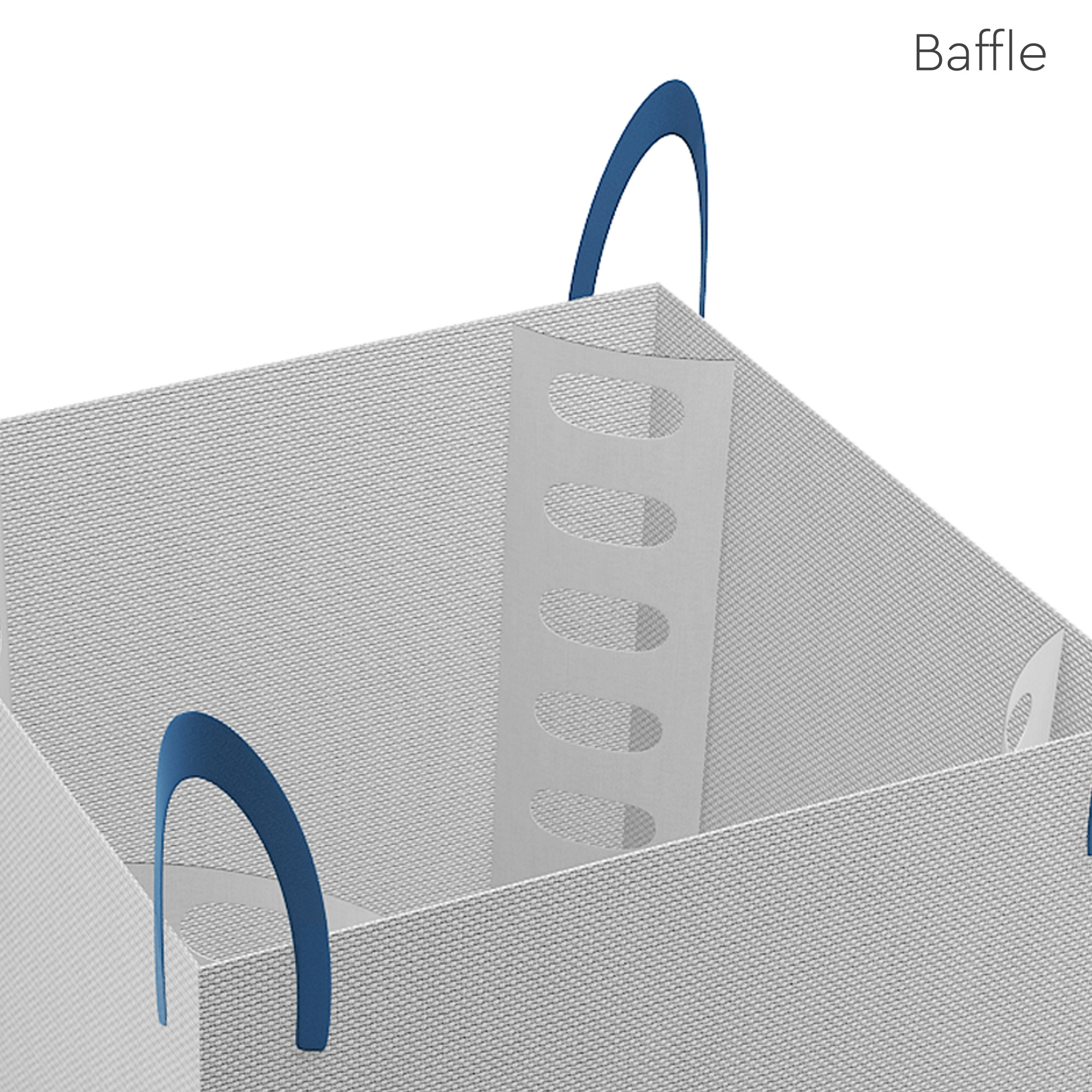

With multiple design options—including U-panel, circular, 4-panel, and baffle constructions—you can choose the right shape and style for your product flow, stacking, and space optimization needs.

Key features include:

- Safe working loads of up to 5,000 lbs.

- Safety factor ratings up to 8:1 for added durability

- Sizing flexibility from 12″ to 56″ in all dimensions

- Optional liners with up to 7-layer coextruded barrier film for added protection

- Custom printing and labeling options are available upon request

Why Virgin Polypropylene Matters

Using 100% virgin polypropylene to manufacture our Type A bulk bags is a strategic choice, not just a material spec.

Because it hasn’t been previously processed, it maintains its full structural integrity, making it ideal for critical applications involving heavy loads, repeated handling, or outdoor exposure.

Here’s why that matters:

- Predictable performance: Virgin PP delivers consistent tensile strength and load-bearing capacity across every bag, helping prevent unexpected failures in the field.

- Improved UV resistance: Fresh polymer chains hold up better against prolonged sun exposure, especially when paired with UV stabilizers—extending bag life in outdoor applications.

- Greater food and pharma compliance: Virgin material minimizes contamination risk, making it the preferred choice for agricultural products, food ingredients, and pharmaceutical-grade goods.

- More precise fabrication: The clean, uniform melt properties of virgin PP support high-quality sealing, stitching, and integration with custom liners or barrier films.

While recycled polypropylene may offer a lower price point, it often comes with trade-offs in safety, durability, and regulatory compliance. That’s why for mission-critical packaging, virgin polypropylene remains the gold standard.

Need help choosing the right style? Our experts can help match you with the ideal build for your workflow. Alternatively, go ahead and request a quote for a prompt response!

What Makes a Type A FIBC Different?

When selecting a bulk bag, it’s essential to understand what distinguishes FIBC Type A from the other types of FIBC bags:

| FIBC Type | Static Protection | Safe for Flammable Dust? | Safe for Explosive Gas/Vapor? |

|---|---|---|---|

| Type A | None | No | No |

| Type B | Minimal (anti-breakdown) | Yes, but not gas/vapor safe | No |

| Type C | Grounded | Yes | Yes |

| Type D | Self-dissipating | Yes | Yes |

We recommend Type A FIBC bulk bags where static build-up is not a risk factor. If you’re unsure, reach out to our team for application-specific guidance.

How Type A Bulk Bags Perform in the Field

While Type A FIBCs are considered general-purpose, their performance in the field makes them a staple across multiple industries. From construction to agriculture, these bags provide the durability and cost-efficiency needed for bulk material handling, especially in environments where static protection is not required.

Construction

Type A bulk bags are widely used for transporting and storing dry, non-flammable materials like gravel, sand, concrete mix, and stone. Their high safe working load (up to 5,000 lbs.) and rugged construction allow for efficient material transfer on job sites, often with the help of forklifts or cranes.

Agriculture

Farmers and ag suppliers use Type A bags to store and move grain, seed, feed, and fertilizer. The bags’ customizable sizing and optional liners make them suitable for moisture-sensitive contents, while their stackability optimizes warehouse and transport space.

Mining & Minerals

Type A FIBCs are often used in non-hazardous mining operations to handle non-combustible ores, powders, and crushed stone. Their sturdy polypropylene construction and large volume capacity enable quick loading, transport, and discharge of bulk raw materials.

Food Processing (Dry Goods)

When static risk is not a factor, food processors use Type A bags to store and transport items like sugar, flour, rice, or salt. Combined with a food-grade liner, these bags help maintain product integrity while streamlining supply chain handling.

Plastics & Manufacturing

In facilities that maintain proper environmental controls, manufacturers use Type A bags to move plastic pellets, resins, and powders. Their flexibility and structural reliability make them a preferred option for non-hazardous storage and shipping.

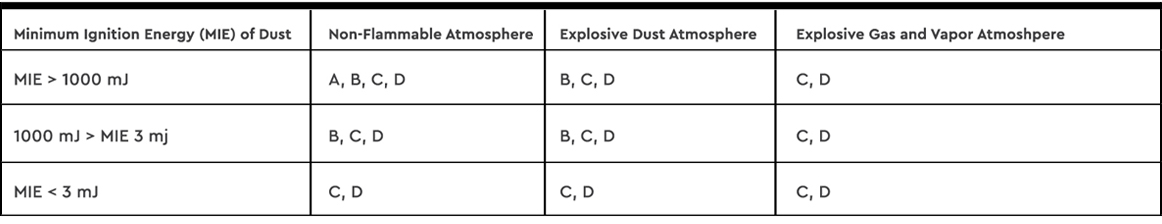

Not sure if Type A bags are suitable for your materials? Use the chart to help identify which type of FIBC is appropriate for your end use, depending on the sensitivity to ignition of the product and the surrounding atmosphere.

Get a Quote on Type A Bulk Bags

At Palmetto Industries, we manufacture and supply Type A FIBCs built to meet your exacting specifications—whether you need high load capacity, optimized liner protection, or custom sizing. All products are made with premium materials and tested for consistent performance.

Need a custom quote? Click below to get a tailored quote from our product specialists.