Why Choose Type B FIBC Bags?

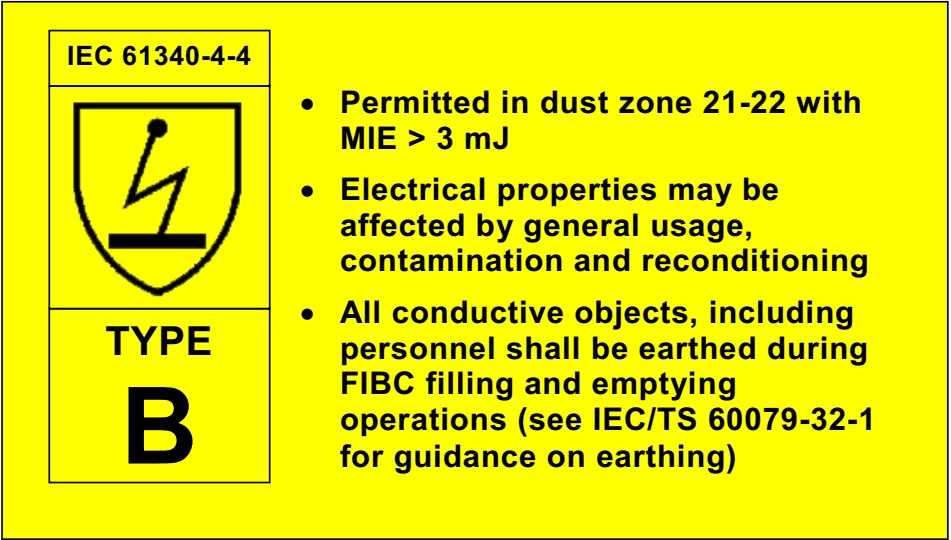

When working with dry, flammable powders, static protection becomes more than just a nice-to-have—it’s essential for safety and compliance. Type B FIBC bags are designed to prevent the risk of brush discharges by using materials with a low breakdown voltage (typically <6 kV), minimizing the potential for dangerous electrostatic sparks.

Although type B FIBC bulk bags don’t dissipate static electricity like Type C or Type D bags, they are a reliable and cost-effective solution for operations where flammable gases and vapors are not present. They provide an added layer of protection compared to Type A bags and are widely used in industries with dust ignition risks, such as agriculture, food processing, and chemicals. Click here to view all of the various construction types.

If you need a tailored quote, reach out to our team by clicking the button below

Type B Bulk Bags Built for Performance

Palmetto’s type B bulk bags are engineered to handle high-capacity loads with safety and consistency. Manufactured with 100% virgin polypropylene, our bags meet stringent durability standards and come in a variety of constructions to match your stacking, filling, and storage needs.

Key features include:

- Safe working loads of up to 5,000 lbs.

- Safety factor ratings of up to 8:1

- Flexible sizing: 12″ to 56″ in length, width, and height

- Optional 7-layer coextruded barrier film liners for moisture-sensitive materials

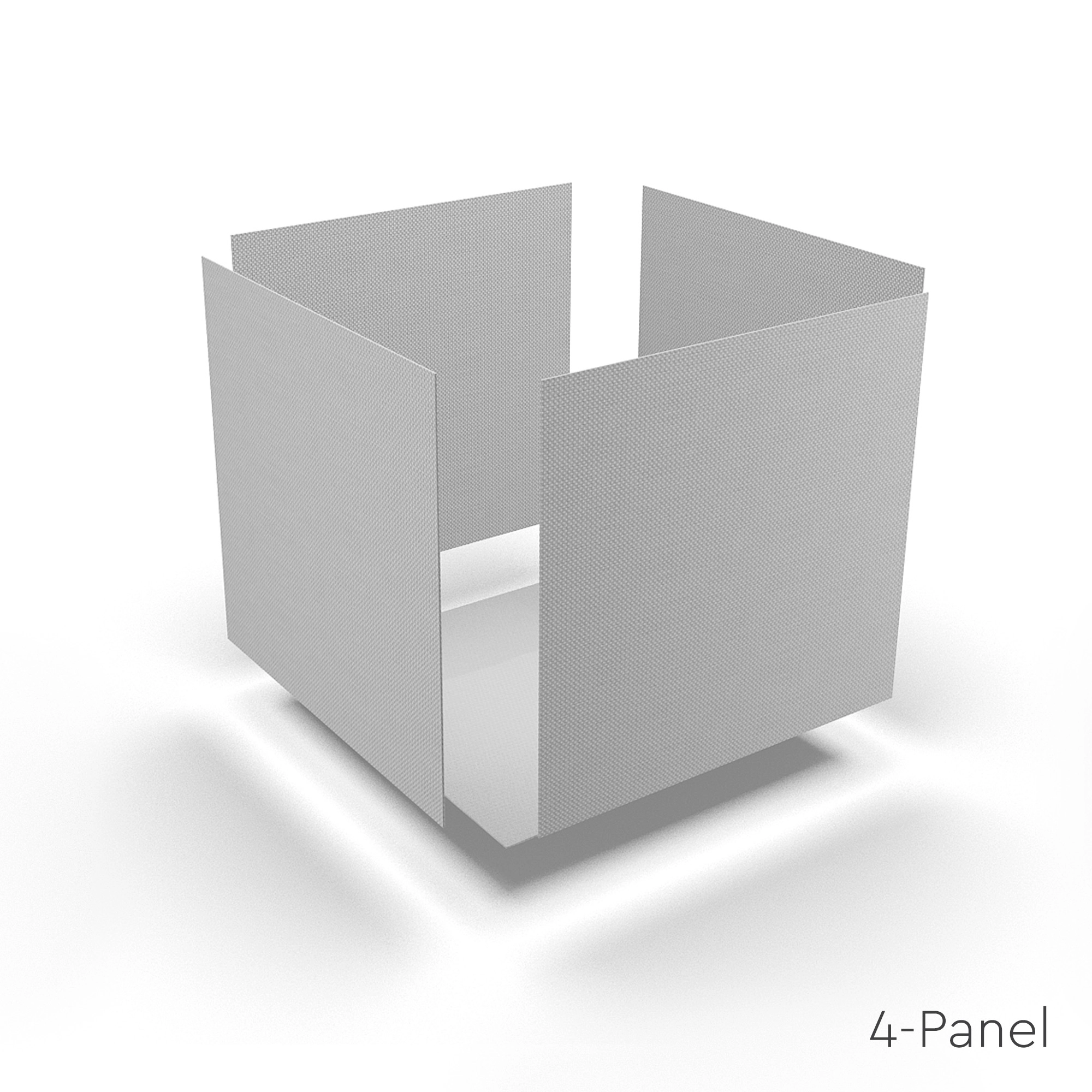

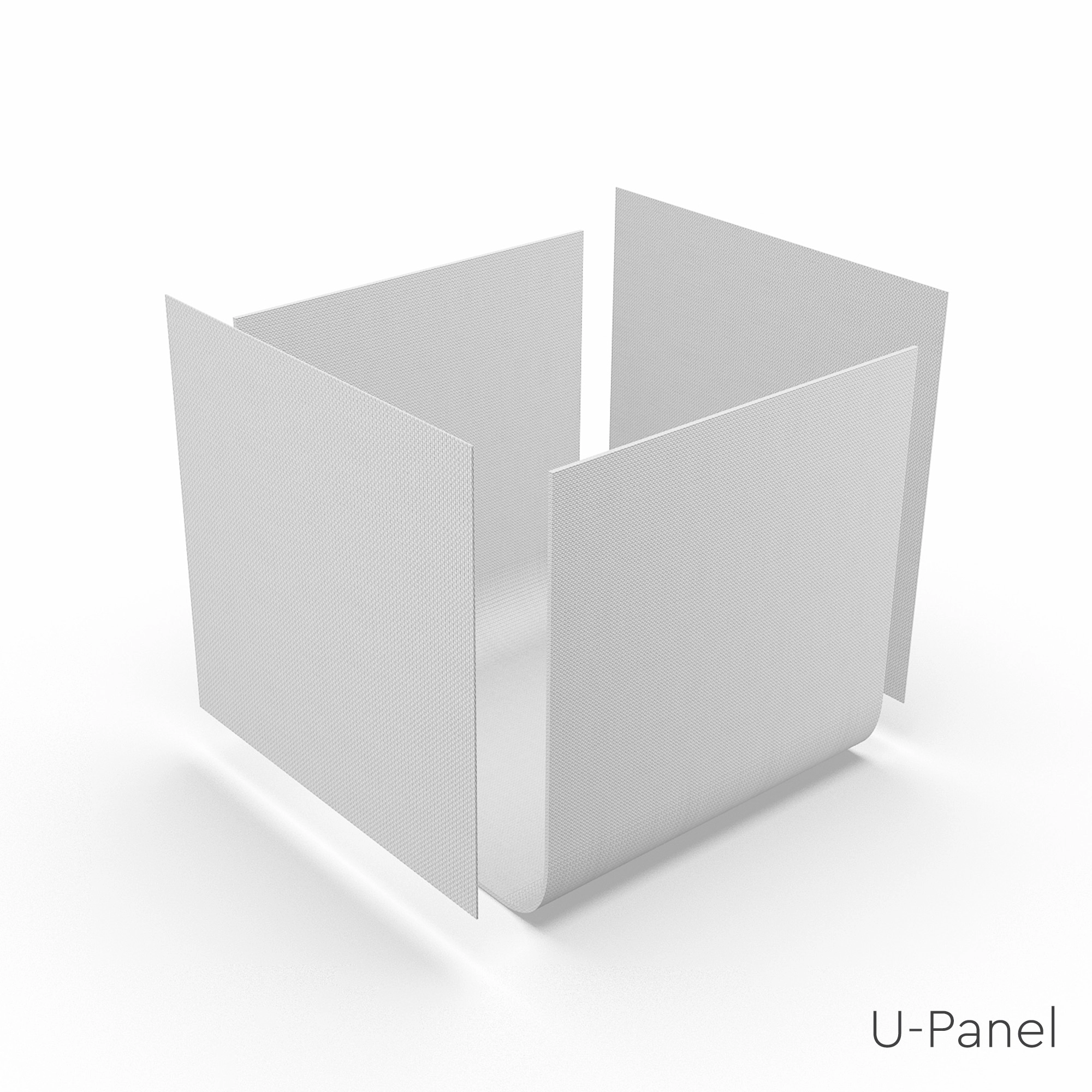

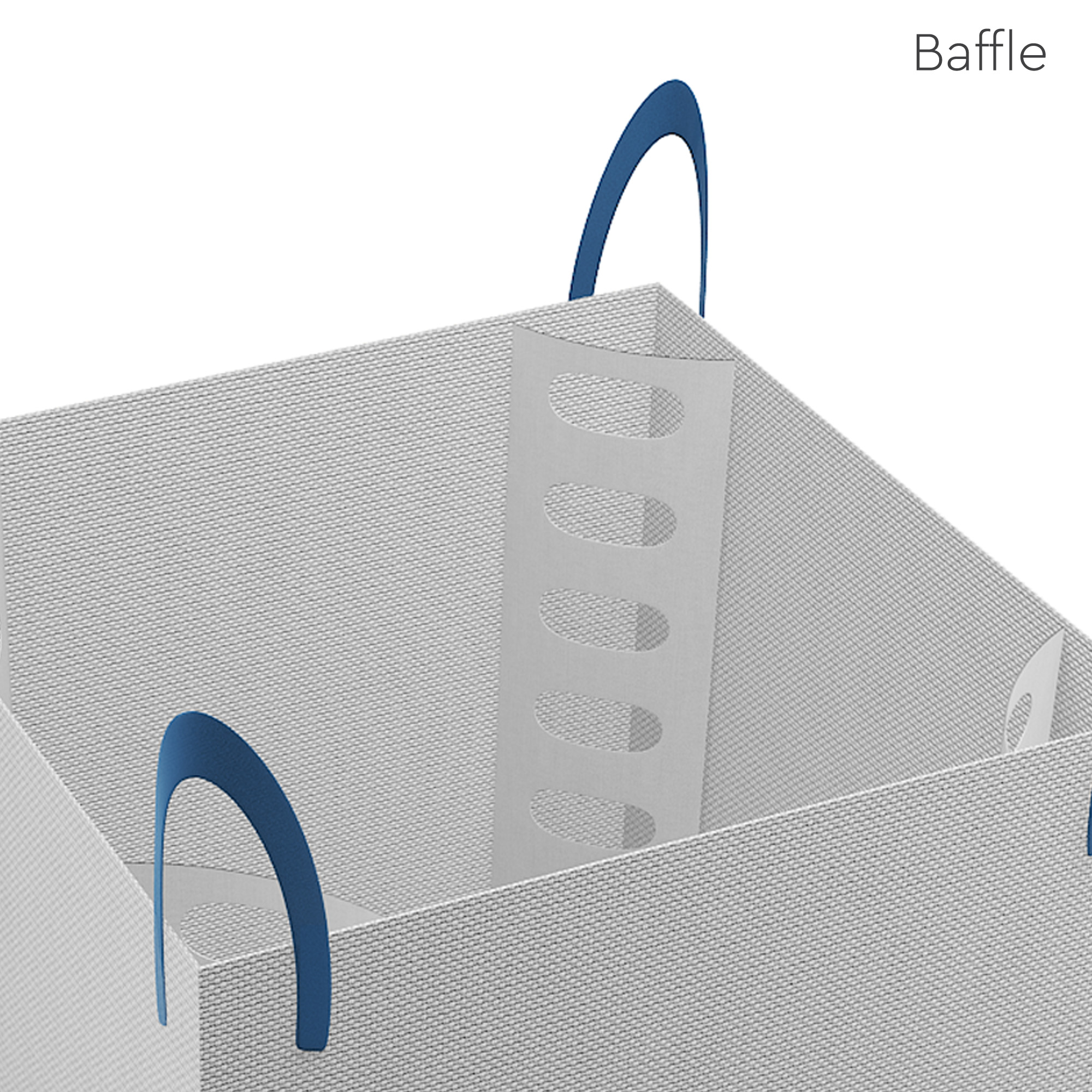

- Available in U-panel, circular, 4-panel, or baffle constructions

Whether you're filling powdered chemicals or agricultural dusts, these bags offer enhanced performance where electrostatic discharges pose a concern, but vapor ignition is not a risk.

Typical Applications for FIBC Type B

FIBC type B bulk bags are best suited for dry, combustible materials that can generate electrostatic charges during filling or discharging, but are handled in environments where no flammable gases or vapors are present.

Below are some of the most common industry applications, along with real-world usage examples.

Chemical Powders

Chemical manufacturers use Type B FIBC bags to transport and store dry compounds like resins, pigments, and mineral additives. These materials can create dust clouds during handling, increasing the risk of static discharge. Type B bags help reduce that risk, particularly in plants that maintain proper airflow and keep flammable solvents out of the packing area.

Example: A specialty pigment supplier uses Type B FIBCs to load 1,500 lbs of dry powder onto pallets in a static-controlled clean room.

Agricultural Products

Farmers, feed producers, and fertilizer distributors rely on Type B bulk bags to store and ship powdered or dusty materials like seed coatings, grain dust, and urea-based fertilizers. These bags are ideal for high-volume loading and help minimize handling risks in dry processing environments.

Example: A regional co-op uses Palmetto Type B bags to package 2,000 lbs of powdered fertilizer per shipment without risking electrostatic buildup in its enclosed facility.

Food-Grade Dry Goods

For non-fat dry foods that are combustible in powdered form—such as sugar, flour, starch, or milk powder—Type B FIBCs offer a safe and hygienic option, especially when paired with a food-safe liner. They prevent brush discharge while keeping contents sealed from moisture.

Example: A flour mill uses Type B bags with form-fit liners to package 1-ton batches for distribution in areas zoned for combustible dust, but free of vapor hazards.

Pharmaceutical Powders

Many pharmaceutical plants use Type B bags to handle powdered active ingredients or excipients during intermediate processing steps. While these bags are not safe for environments with flammable vapors, they provide dust containment in controlled facilities with strict static protocols.

Example: A contract manufacturer uses Type B FIBCs to move 500 kg batches of fine excipients in an ATEX-compliant, but vapor-free, environment.

Plastics and Additives

The plastics industry often uses Type B bulk bags for colorants, fillers, and regrind dust—all of which pose electrostatic risks when conveyed or transferred. The low breakdown voltage of Type B fabric helps reduce the chance of ignition during transfer in dry, well-ventilated zones.

Example: A resin compounder packages pigment dust into Type B FIBCs on a slow-fill line with grounded metal conveyors to limit charge accumulation.

How FIBC Type B Compares to Other Bulk Bags

Choosing the right bulk bag type depends on your material and operating environment. To help you decide, we’ve included a quick-reference chart below comparing the different types of bulk bags based on their suitability for static-sensitive applications:

| FIBC Type | Static Protection | Use With Flammable Dust | Use With Flammable Gases/Vapors |

|---|---|---|---|

| Type A | None | No | No |

| Type B | Low breakdown voltage (<6 kV) | ✅ Yes | ❌ No |

| Type C | Must be grounded | ✅ Yes | ✅ Yes |

| Type D | Self-dissipating material | ✅ Yes | ✅ Yes |

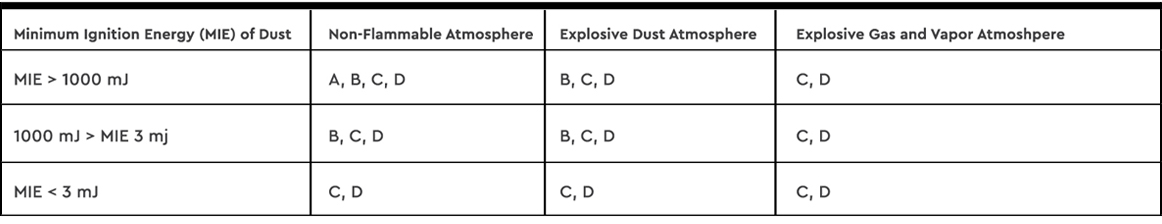

Use the chart below to help identify which type of FIBC is appropriate for your end use, depending on the sensitivity to ignition of the product and the surrounding atmosphere.

What is Breakdown Voltage?

Breakdown voltage refers to the point at which an insulating material, like the fabric used in bulk bags, can no longer resist an electrical charge. When voltage exceeds this limit, it can jump through the material as a spark or arc, which is dangerous when handling combustible dust.

Type B FIBC bags are made with fabric that has a breakdown voltage of less than 6 kilovolts (kV). This helps prevent brush discharges, which are a common source of ignition in dusty environments. While these bags don’t actively dissipate static like Type C or D FIBCs, they help reduce the risk of electrostatic ignition during routine handling, especially when filling or discharging fine, dry powders.

Safety Best Practices for Type B Bulk Bags

While Type B bulk bags are designed to reduce static hazards in dusty conditions, it’s important to use them properly to maintain safety and compliance. Follow these best practices to ensure safe handling:

- Never use in environments with flammable gases or vapors. Type B bags do not offer protection in those settings.

- Avoid fast filling or discharging. Rapid material movement increases the chance of static buildup.

- Ground nearby conductive equipment. Any metal object within 1 meter of the bag should be grounded to prevent charge accumulation.

- Inspect before each use. Look for damage to seams, fabric, or lifting loops before loading.

- Pair with liners when needed. For powders that are sensitive to moisture or contamination, use a coextruded liner designed for static-safe applications.

These precautions are essential in industries like chemicals, agriculture, and food processing—where dry materials are common, but vapor ignition isn’t a concern.

Request a Quote for Type B Bulk Bags

Palmetto Industries supplies type B bulk bags to industries where safety, quality, and consistency matter most. Every bag is manufactured with precision and tested to meet the demands of real-world handling—from forklift loading to high-volume powder filling.

Ready to place an order or customize your Type B FIBC? Click below to get started.

Type B Bulk Bags FAQs

What happens if Type B bags are used near flammable vapors?

Using Type B FIBC bags near flammable vapors is unsafe and violates their intended use. These bags do not dissipate static electricity and can allow dangerous spark discharges in the presence of flammable gases. For vapor-sensitive environments, Type C or D FIBCs are the appropriate and compliant alternatives.

Can Type B FIBC bags be used in ATEX Zone 22 environments?

Yes, Type B FIBC bags can be used in ATEX Zone 22 environments, provided there are no flammable gases or vapors present. Zone 22 typically involves occasional or short-term exposure to combustible dust, which Type B bags are designed to handle when static control procedures are also in place.

How do I know if I need Type B or Type C bulk bags?

If you’re handling dry combustible materials in a vapor-free setting, Type B may be sufficient. However, if your environment includes flammable gases, solvents or has grounding capabilities, Type C bags offer safer static discharge control. Use your facility’s safety classification and hazard assessments to determine the correct type.

Can I add a liner to a Type B bag for extra protection?

Yes, Type B FIBCs can be used with liners, such as form-fit or tubular coextruded liners, to protect contents from moisture, contamination, or oxygen exposure. However, ensure the liner does not increase static risk. For static-sensitive applications, always consult your supplier about compatible, antistatic liner options.

Are there filling or discharging speed limits for Type B FIBCs?

Yes, excessive filling or discharging speeds can lead to static buildup, increasing the risk of electrostatic discharge. While there’s no universal speed limit, slower fill rates, proper grounding of nearby equipment, and controlled dust ventilation are best practices when using Type B bags in dry material handling.