Why Choose Type C Bulk Bags?

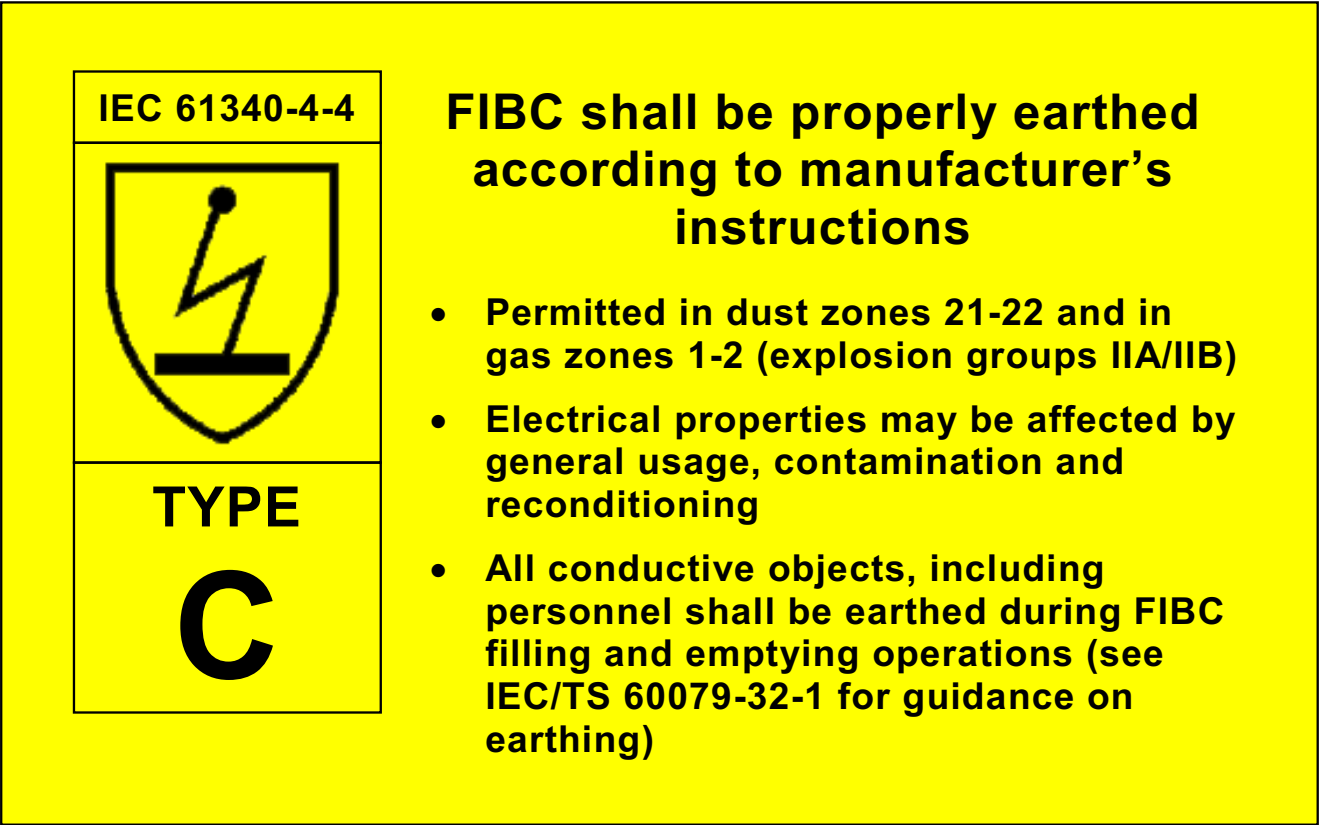

When safety is non-negotiable, type C bulk bags offer dependable static protection in high-risk environments. These bags are constructed from groundable polypropylene fabric interwoven with conductive threads. They are specifically designed to safely dissipate static electricity when properly grounded, reducing the risk of electrostatic discharge (ESD) in operations where flammable gases, vapors, or combustible dusts are present.

Our FIBC type C at Palmetto Industries is the go-to solution for industries like chemicals, food processing, pharmaceuticals, and industrial manufacturing—anywhere that static buildup could become a serious ignition hazard.

If you need a tailored quote, reach out to our team by clicking the button below

FIBC Type C Specifications

Our type C FIBC lineup is engineered for high-risk environments where static discharge is a serious concern. Every bag is built with performance, safety, and compliance in mind, backed by materials and design choices that help you meet regulatory standards and operate with confidence.

Here’s a breakdown of the specifications and why they matter:

Material: Groundable polypropylene fabric with interwoven conductive threads

This fabric is the core safety feature. The conductive threads allow static electricity to travel through the bag and safely discharge when properly grounded. Without this, the bag would behave like a standard Type A or B, making it unsuitable for flammable or explosive environments.

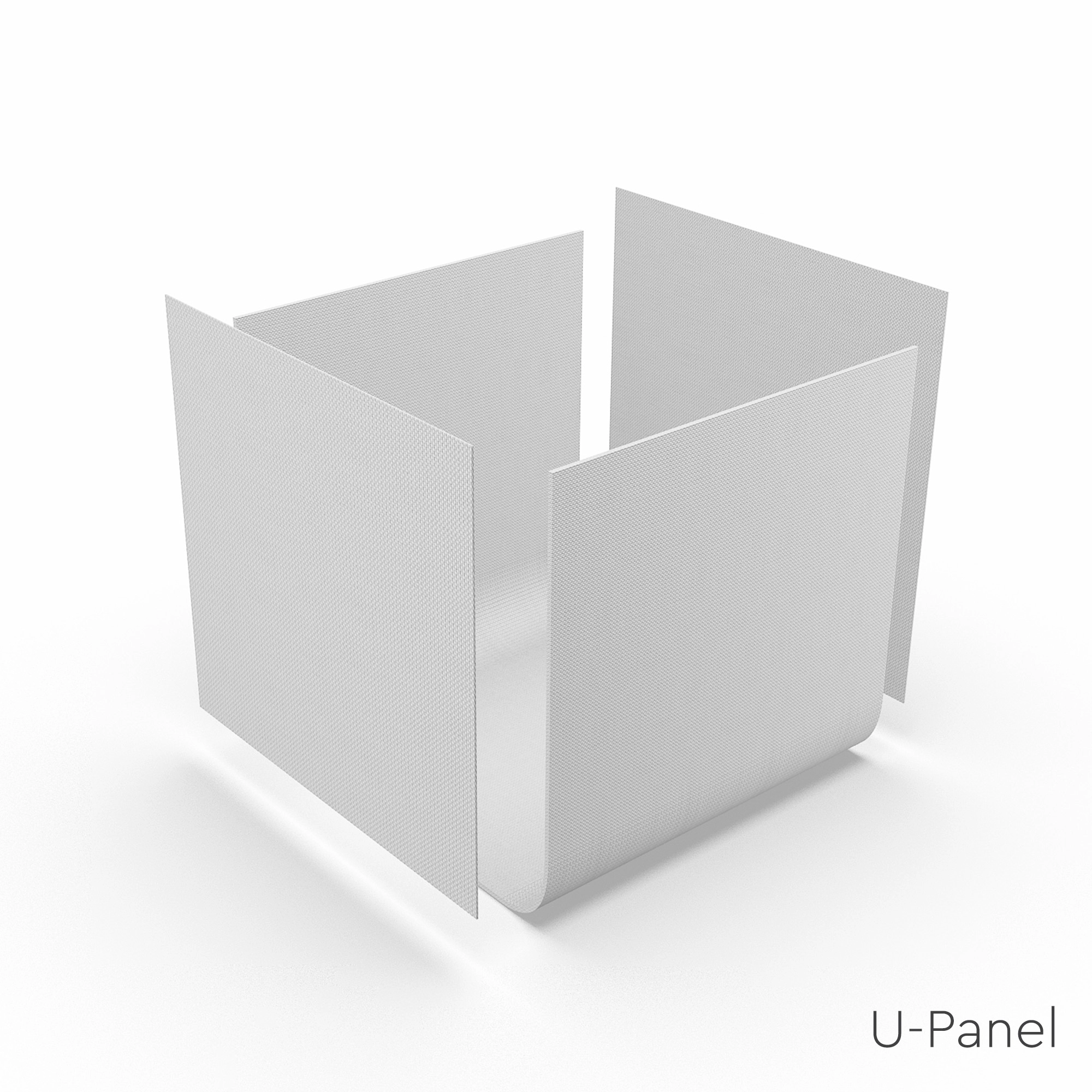

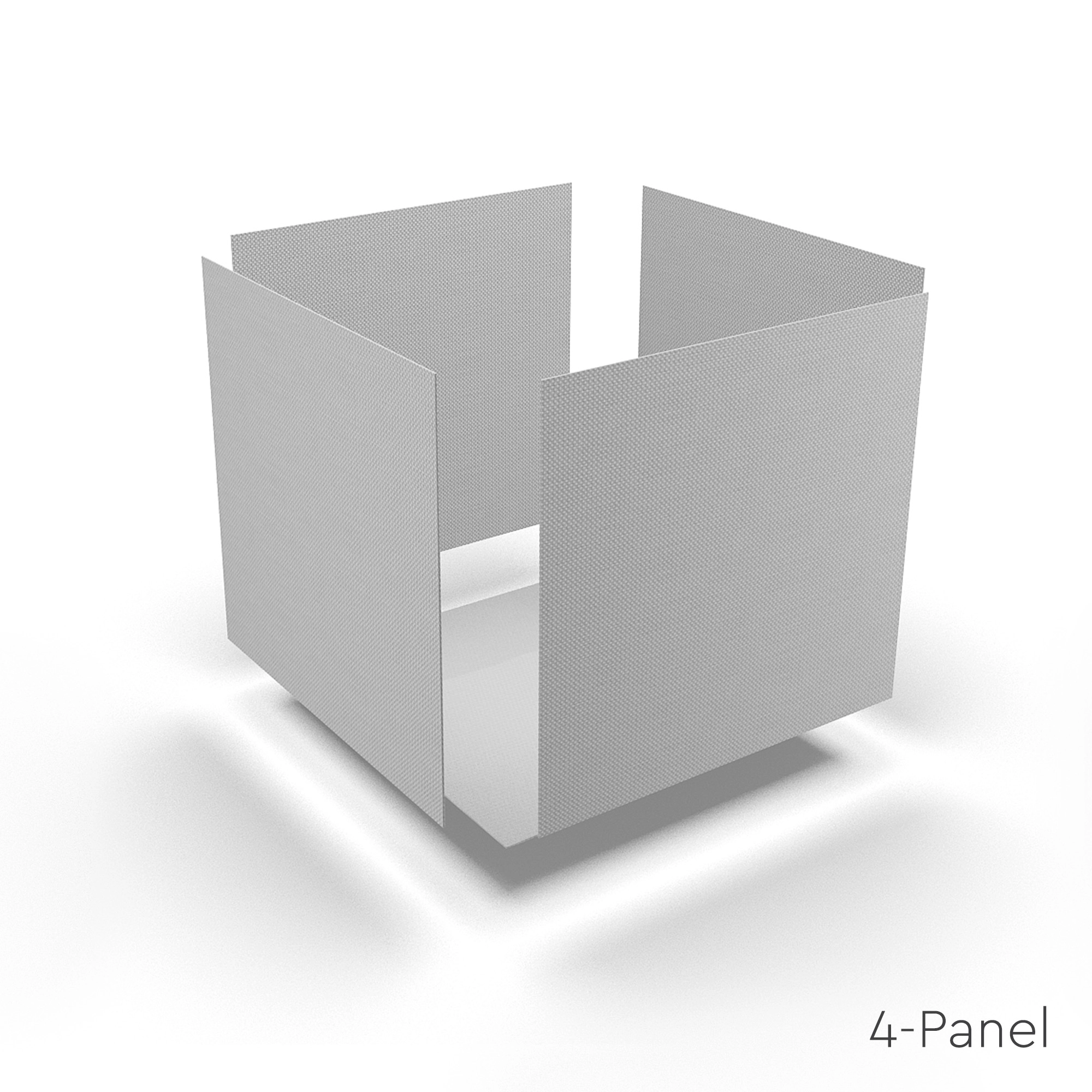

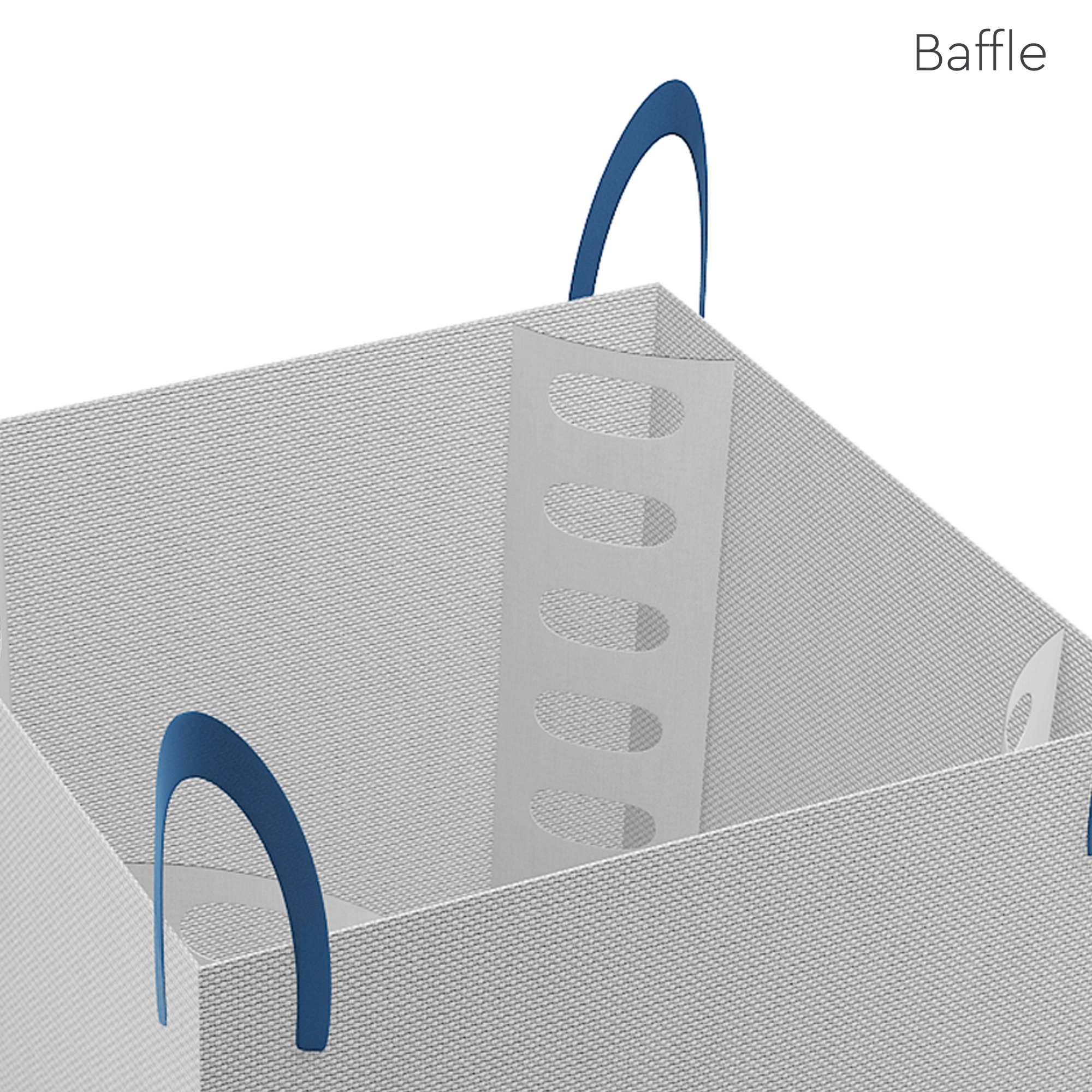

Construction options: U-Panel, Circular, 4-Panel, or Baffle

These structural formats impact how the bag fills, discharges, and stacks. For example, baffle bags are ideal for tight storage spaces because they retain a square shape, while U-panel bags are more cost-effective for general use. Choosing the right construction helps you maximize efficiency and product flow.

Safe Working Load: Up to 3,000 lbs.

This rating reflects how much material the bag can safely hold. Knowing your material density and shipment size will help determine whether this capacity fits your operation. For high-volume or heavier materials, ensuring you’re within the bag’s SWL is critical to avoid rupture or tipping hazards.

Safety Factor: Up to 8:1

This represents the bag’s strength under stress, tested well beyond its maximum working load. An 8:1 safety factor is essential for multi-use applications or if you’re handling high-value materials that demand reliable containment and reuse without risk of failure.

Liner Options: Up to 7-layer coextruded barrier film

Liners are used to protect contents from moisture, oxygen, or contamination—especially important for powders or hygroscopic materials like flour, starch, or pharmaceutical ingredients. The multi-layer structure enhances protection and integrity, particularly in humid or sensitive environments.

Dimensions: Length, width, and height from 12″ to 56″

Custom sizing ensures that your bag fits your material volume, warehouse layout, and shipping configuration. Undersized or oversized bags can lead to inefficient stacking, overfilling, or underutilization of transport space.

By understanding how each spec impacts safety, usability, and efficiency, you can confidently choose the right FIBC type C configuration for your process.

Still unsure? Reach out to our product experts for further guidance on your specific needs

When to Use a Type C FIBC

Type C FIBC bags should be used in any settinghttps://www.palmetto-industries.com/contact-us/ where:

- Combustible dusts, flammable gases, or vapors are present

- There is a risk of electrostatic buildup during filling or discharge

- Strict static control procedures are required for operational safety

- Compliance with IEC 61340-4-4, ATEX Zone 1/2, or NFPA 77 is essential

Important: Type C bags must always be grounded during use. Failing to connect the conductive loops to a proper ground can void the static protection and compromise safety.

Typical Applications for FIBC Type C

Below are the most common applications where our FIBC type C bags provide both safety and operational reliability.

Chemical Processing

Used to handle volatile powders and compounds in mixing, packaging, and transfer operations. Type C bags reduce the risk of ignition near solvents, peroxides, or other flammable chemicals.

Pharmaceuticals

Ideal for transporting powdered active ingredients or excipients where strict cleanliness and ESD protection are required. Often used in ATEX-classified clean rooms.

Food Manufacturing

Used for dry food ingredients like flour, sugar, and starch in environments where dust clouds and combustible conditions are possible.

Coatings and Paints

Commonly used for transferring colorants, powdered resins, or additives that may generate static charges when moved or poured.

Additive Manufacturing

In newer applications like 3D printing powder handling, Type C bags offer safe packaging for conductive and flammable metal powders.

How Type C Bulk Bags Work

Type C bulk bags use interwoven conductive threads within the polypropylene fabric. These threads are all electrically interconnected and designed to be attached to a grounding point during use.

Once grounded, the bag safely dissipates any static electricity generated during filling or discharge, preventing brush discharges, spark discharges, or propagating brush discharges that could ignite combustible materials in the surrounding environment.

Without grounding, the bag functions like a Type B, offering no meaningful ESD protection. That’s why proper grounding procedures are critical for safe operation.

FIBC Type C vs Other Bulk Bags

To help guide your purchasing decision, use the table below to understand how Type C FIBC bags compare to Types A, B, and D across key safety categories:

| FIBC Type | Static Protection | Use With Flammable Dust | Use With Flammable Gases/Vapors |

|---|---|---|---|

| Type A | None | ❌ No | ❌ No |

| Type B | Low breakdown voltage | ✅ Yes | ❌ No |

| Type C | Groundable conductive fabric | ✅ Yes | ✅ Yes |

| Type D | Static-dissipative material | ✅ Yes | ✅ Yes |

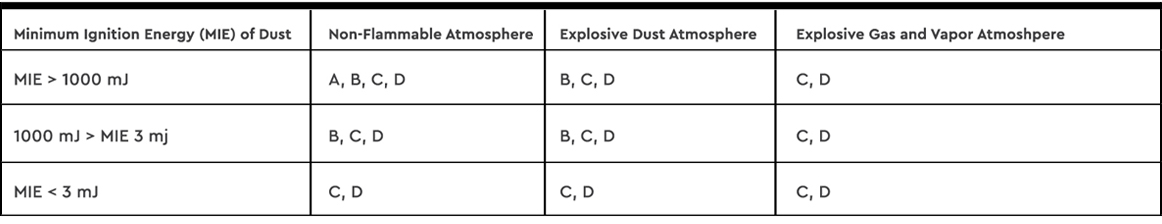

Use the chart to help identify which type of bulk bag is appropriate for your end use, depending on the sensitivity to ignition of the product and the surrounding atmosphere.

Need help choosing the right FIBC type? Contact us for application-specific guidance from our team of bulk packaging experts.

General Information Relating to Our Type C Bulk Bags

The Risk of Static Ignition

Electrostatic discharge is a leading cause of ignition in combustible dust explosions, especially in powder handling environments. That’s why selecting the right FIBC isn’t just a matter of preference, it’s a key part of your facility’s risk mitigation strategy.

At Palmetto Industries, we don’t just sell bags, we help buyers navigate complex decisions. We’ll walk you through the ESD considerations, grounding protocols, and zone classification requirements to ensure your operation stays compliant and safe.

The Grounding Process Explained

Proper grounding is the most critical factor when using Type C bags. Here’s how it works:

- Attach the conductive loop or grounding tab of the FIBC to a known ground point.

- Use a verified ground monitoring system when available to ensure the connection is continuous.

- Inspect the loop, fabric integrity, and any terminals before every use.

- Train staff to never fill or empty a Type C bag unless it is actively grounded.

This process is simple but essential, and is often overlooked in operations that haven’t standardized their grounding procedures.

Request a Quote for Our Type C FIBC Bulk Bags

Palmetto Industries provides Type C bulk bags built for high-risk environments and tested for safe performance under the most demanding static-sensitive conditions. Whether you're in chemical production, food manufacturing, or powder processing, we’ll make sure your bags meet regulatory and operational expectations.

Ready to get started? Request a quote or contact our team to review your application and compliance requirements.

Type C Bulk Bags FAQs

What happens if a Type C bulk bag is not grounded properly?

If a Type C bulk bag is not properly grounded, it loses its ability to safely dissipate static electricity. This can lead to dangerous spark discharges during filling or discharging, which may ignite flammable gases, vapors, or dust. Grounding is critical to maintain the bag’s static protection performance.

Can Type C FIBCs be reused safely in hazardous environments?

Type C FIBCs can be reused in hazardous environments if they are in good condition and have been inspected thoroughly. However, grounding loops and conductive threads must remain fully intact. Regular inspections, cleaning protocols, and strict grounding procedures are essential before reuse to ensure continued static protection.

How do I verify if a Type C bag is properly grounded?

Proper grounding can be verified using a continuity tester or ground monitoring system. The conductive threads and grounding tab should show electrical continuity to the grounding point. Always check for physical connection and use visual indicators or alarms if your facility employs static control monitoring devices.

Are liners in Type C bags also conductive or antistatic?

Not all liners in Type C bags are antistatic or conductive. Standard liners can hinder static dissipation if not compatible. For static-sensitive applications, always request liners specifically designed for use in grounded systems, such as those made from antistatic materials or approved conductive polymers.

What certifications should I look for in compliant Type C bulk bags?

Look for compliance with IEC 61340-4-4, ATEX Zone 1 or 2 suitability, and NFPA 77 guidelines. Reputable manufacturers should be able to provide testing documentation, certification of the conductive fabric, and guidance on proper use in hazardous or explosive atmospheres. Always verify with your supplier.