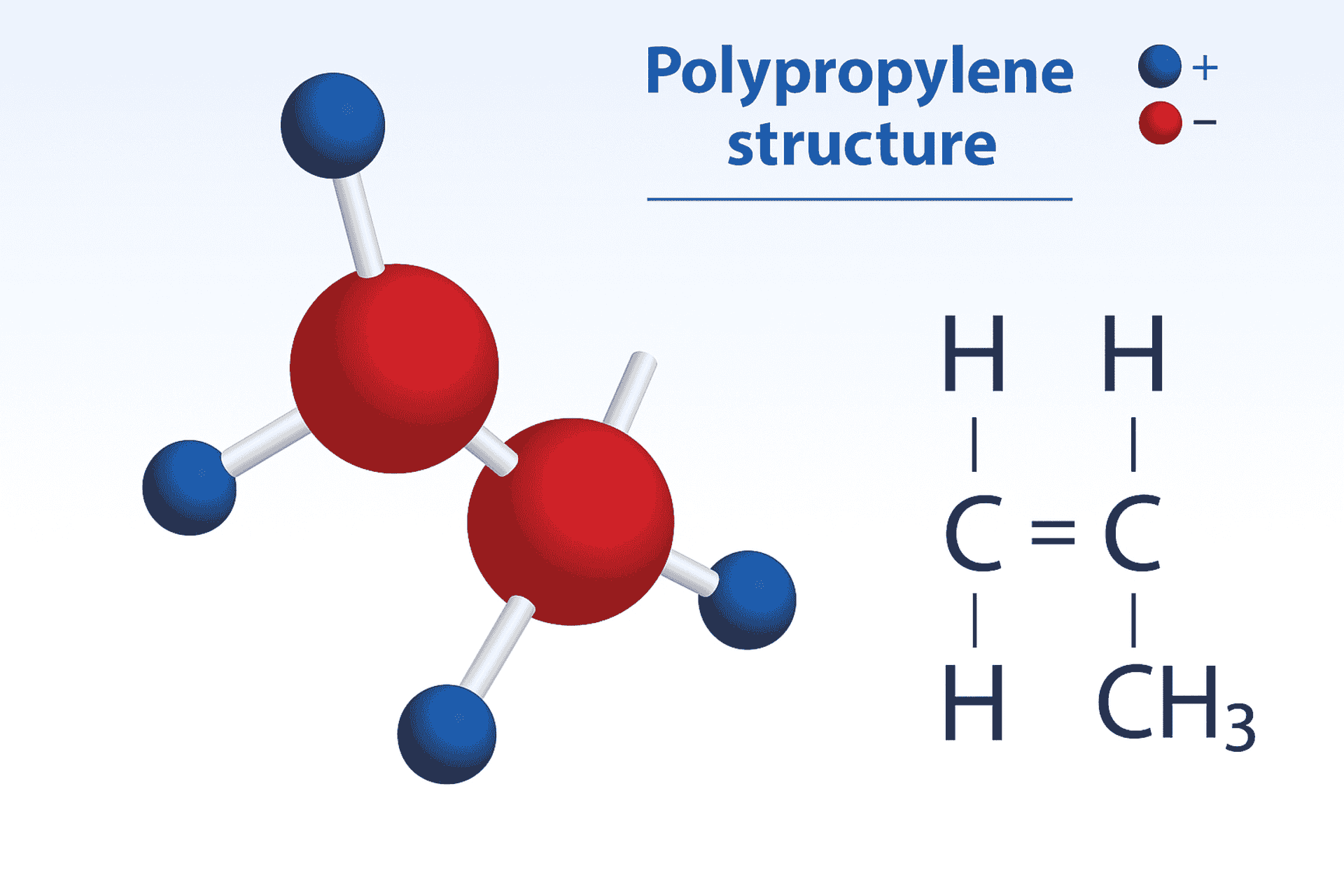

Polypropylene Properties & Polypropylene Characteristics Explained

Getting to know polypropylene properties and polypropylene characteristics is essential when choosing the right material for industrial, commercial, or consumer applications. Known for its strength, flexibility, and chemical resistance, polypropylene is a lightweight thermoplastic used in everything from packaging and automotive parts to textiles and medical components.

This versatile polymer offers excellent impact resistance, moisture resistance, and heat tolerance, making it suitable for high-performance environments. Now, lets take a closer look at the key mechanical, thermal, and chemical traits that make polypropylene one of the most widely used plastics in the world today.

Polypropylene properties and characteristics

The material properties of polypropylene make it one of the most widely used plastics across industries. From its excellent chemical resistance and mechanical strength to its lightweight structure and flexibility, polypropylene is valued for both its versatility and cost-effectiveness.

Looking for reliable packaging solutions? Explore our high-quality PP woven fabric rolls for durable, industrial-grade performance.

Polypropylene mechanical properties

Polypropylene (PP) is known for a strong balance of mechanical performance and lightweight structure, making it a go-to material in applications ranging from automotive components to packaging films.

Below is a breakdown of essential PP properties that influence how it performs under mechanical stress.

- Density: With a density of 0.90–0.91 g/cm³, polypropylene is among the lightest thermoplastics. Its low weight combined with strength makes it ideal for automotive and aerospace applications where weight reduction is key.

- Elongation at Break: Polypropylene has an elongation at break of 200–700%, depending on grade. This high elasticity makes it ideal for thin films, fiber applications, and flexible molded parts.

- Fatigue Resistance: One of polypropylene’s standout features is its excellent fatigue resistance, meaning it can endure repetitive bending without cracking. This is especially useful for living hinge designs, like flip-top bottle caps.

- Flexural Modulus: With a flexural modulus of 1,200–1,500 MPa, polypropylene demonstrates good stiffness while allowing some flexibility. This property is valuable in applications like living hinges, packaging containers, and storage bins.

- Hardness: Polypropylene ranks 70–90 on the Shore D scale, making it semi-rigid yet tough. It is used in containers, caps, and lightweight mechanical parts that need moderate hardness with flexibility.

- Impact Strength: Impact strength for polypropylene typically falls between 5–10 kJ/m². It resists cracking under sudden impact, which is why it’s used for automotive bumpers, tool housings, and reusable crates.

- Tensile Strength: Polypropylene has a tensile strength of 30–50 MPa, which allows it to resist being pulled apart under tension. This makes it suitable for products like straps, ropes, and molded parts that need to maintain shape under load.

| Mechanical Property | Polypropylene | Polyethylene | Polyester |

|---|---|---|---|

| Tensile Strength (MPa) | 30–50 | 20–40 | 50–90 |

| Flexural Modulus (MPa) | 1,200–1,500 | 1,000–1,300 | 2,500–3,000 |

| Impact Strength (kJ/m²) | 5–10 | 3–8 | 3–6 |

| Elongation at Break (%) | 200–700 | 500–900 | 50–150 |

| Hardness (Shore D) | 70–90 | 60–70 | 85–95 |

| Density (g/cm³) | 0.90–0.91 | 0.91–0.96 | 1.38–1.41 |

These values may vary slightly depending on the specific type of polypropylene used, such as homopolymer or copolymer grades, and the presence of fillers or additives for enhanced performance in outdoor applications, high-impact parts, or chemical environments.

Polypropylene physical properties

When selecting materials for packaging, industrial design, or product manufacturing, knowing PP plastic properties is essential. Polypropylene offers a combination of low density, high temperature resistance, and excellent moisture resistance, making it one of the most widely used thermoplastics in global industries.

Below, we break down the most important physical properties of polypropylene, how they compare to other materials, and where they offer an advantage in real-world applications.

- Density: Polypropylene has a density of approximately 0.90 g/cm³, it is one of the lightest commercial plastics which is one reason why there are so many polypropylene uses. This property makes it ideal for automotive parts, packaging, and geotextiles, where reducing weight without sacrificing strength is a priority.

- Melting Point: Is polypropylene heat resistant? The answer is yes! The polypropylene melting point ranges from 160°C to 170°C, depending on the specific grade. It holds its form well at elevated temperatures, making it suitable for hot-fill food containers and sterilizable medical devices.

- Moisture Absorption: Polypropylene has a very low moisture absorption rate—typically under 0.03%—which helps it maintain mechanical strength and shape even in wet or humid conditions. This property is especially important in geotextile applications, where the differences between woven vs non-woven geotextile performance is important for long-term ground stabilization and drainage.

- Surface Hardness: Polypropylene offers moderate surface hardness—enough to resist scratches and minor wear, making it a good choice for reusable consumer goods, bins, and containers. It is tough enough for impact resistance but soft enough for easy handling and flexibility.

- Transparency and Appearance: PP is typically opaque or translucent, depending on processing and additives. While not as clear as some plastics, its semi-gloss surface makes it ideal for household items, packaging films, and consumer containers.

- Thermal Expansion: Polypropylene has a higher coefficient of thermal expansion than some engineering plastics, which means it can slightly change shape with temperature fluctuations. This property is manageable in most indoor applications, but may require reinforcement in high-heat environments.

Polypropylene characteristics

In addition to its well-known mechanical and physical traits, polypropylene is valued for a range of observable and performance-based characteristics that make it suitable for countless real-world applications. These features influence how the material behaves in different environments and under various forms of use.

Here is a breakdown of important polypropylene characteristics that help explain why it remains one of the most widely used polymers globally.

- Chemical Resistance: Polypropylene exhibits excellent resistance to most acids, bases, and organic solvents, making it suitable for chemical storage containers, lab equipment, and pipes. It can handle exposure to alkalis and harsh cleaning agents without degrading, which also makes it popular in medical and food packaging.

- Color and Finish: Polypropylene is naturally opaque or translucent, but it takes colorants well during production, allowing for a wide variety of hues and finishes. This makes it ideal for consumer goods, toys, branded packaging, and decorative household items.

- Ease of Processing: Polypropylene is easily processed via injection molding, blow molding, and sheet extrusion, making it one of the most versatile plastics in manufacturing. Polypropylene sheet uses range from storage bins and medical trays to industrial barriers and custom cut panels.

- Electrical Insulation: PP is an excellent electrical insulator, even under high humidity. It’s widely used in electronic housings, wiring components, and anti-static materials when modified with conductive additives. Its insulation properties are especially useful in automotive and appliance manufacturing.

- Environmental Impact and Recycling: PP is a recyclable thermoplastic, commonly identified as resin code #5. Through PP recycling, it’s reprocessed into products like storage containers, automotive parts, and textile fibers. Its low energy input during production also makes it a favorable material in sustainability-focused industries.

- Flammability: Polypropylene is considered flammable and can ignite when exposed to open flame. It has a flashpoint of around 260°C (500°F). Due to this, flame retardants are often included in building products and electronics where materials and flame resistance are required.

- UV Resistance: While raw polypropylene is sensitive to UV degradation, its UV resistance improves significantly with stabilizers or additives. For outdoor uses, such as woven geotextiles or agricultural tarps, UV inhibitors are added during the polypropylene manufacturing process to prevent the material from becoming brittle over time.

| Characteristic | Polypropylene | Polyethylene | PVC |

|---|---|---|---|

| Chemical Resistance | Excellent (resists most acids/alkalis) | Good (resists common chemicals) | Moderate (can be attacked by some acids) |

| UV Resistance | Moderate to High (with stabilizers) | Low (susceptible to degradation) | High (with additives) |

| Thermal Resistance | -20°C to 100°C | -50°C to 80°C | -15°C to 60°C |

| Flammability | Flammable (ignites at ~260°C) | Flammable | Self-extinguishing (with additives) |

| Color/Finish | Opaque/translucent; accepts color well | Translucent; limited color range | Opaque; easily colored |

| Electrical Insulation | Excellent | Good | Excellent |

| Recyclability | High (PP recycling, resin code #5) | High (resin code #2 or #4) | Limited due to additives |

| Processability | Excellent (molding, extrusion, thermoform) | Excellent | Moderate |

Trust Palmetto Industries for world-class polypropylene products

When it comes to high-performance polypropylene products, Palmetto Industries stands out as a reliable, experienced partner serving industries across the globe. Whether you need homopolymer or copolymer forms, our polypropylene is engineered to meet the needs of medical devices, household appliances, outdoor applications, and more.

Our deep knowledge of the characteristics of polypropylene—including its low density, heat resistance, good impact resistance, and chemical stability—allows us to offer materials suitable for injection molding, packaging films, and 3D printing. From plastic products to packaging films, we support applications where weight, strength, and ease of processing are critical.

With expertise in various types of polypropylene, including those with high or lower melting points, we tailor our solutions for applications that require dimensional stability, UV protection, solvent resistance, or recyclability. Whether you’re working with polymer chains, propene, or specific types of fillers and pigments, we’ll help you select the right grade and format—from pellet to sheet.

Ready to find the right polypropylene solution for your business? Contact us today to speak with our expert team.

Key takeaways on polypropylene material properties

Polypropylene is a thermoplastic polymer known for its light weight, good chemical resistance, low moisture absorption, and high melting point. First polymerized in 1951 from propylene monomers, it’s widely used in packaging, automotive parts, medical devices, and disposable products.

Its crystalline structure, toughness, and processability make it ideal for applications where high impact strength, heat resistance, and dimensional stability are required. Though flammable and UV-sensitive, additives can improve performance.

Polypropylene is also recyclable, easy to mold, and offers strong performance compared to other engineering plastics—making it a go-to material for industries worldwide.